The APW100 Airframe Protection Series Taking the Aviation Industry into the 21st Century With New Corrosion Prevention Technology

Superior Protection

More durable compared to traditional corrosion inhibiting compounds (CIC)

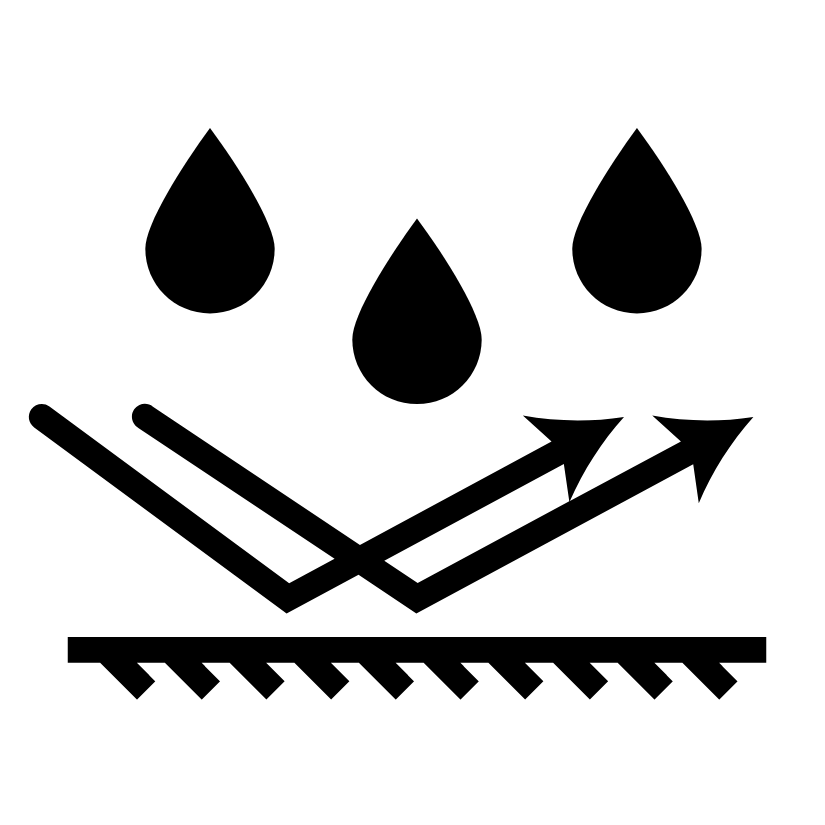

Water-Based Technology

Cost & Time Savings

Environmentally Friendly

AeroPel is a nanocomposite protective layer (NPL) is formulated to provide superior protection for airframe structures and components. AeroPel NPL is the next generation in corrosion prevention, with other benefits and applications yet to be imagined.

How can AeroPel better protect against corrosion?

With a superior bond strength to the substrate, resistant to chemicals and abrasion, AeroPel NPL provides a robust protection for both bare metal and existing organic-based protective measures. AeroPel NPL is inherently durable and outperforms traditional organic-based corrosion inhibiting compounds.

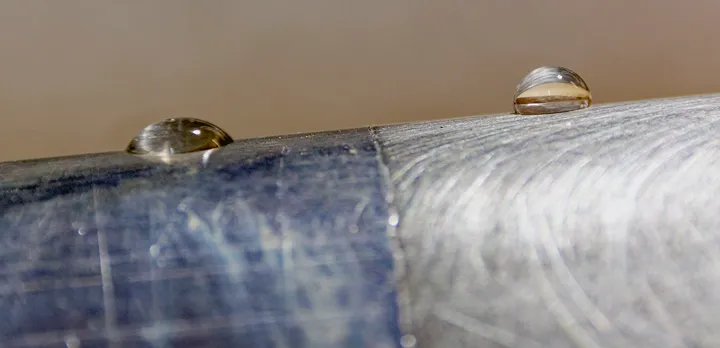

Low Surface Energy Concept – The water droplet on the left is placed on a bare aluminum surface compared to the water droplet on the right is placed on a surface protected by the NPL. Note the NPL is forcing the droplet to bead up instead of wetting the surface.

AeroPel NPL cures under one hour to the touch to reduce workflow interruption. In addition, with zero VOC, workflow in confined space can progress during the application process to maintain productivity.

Key Benefits

Example of failing traditional Corrosion Inhibiting Compound (CIC)

Fuselage skin corrosion damage: exhaust vent moisture penetrated organic-based topcoat, primer, and chemical conversion.